The latest industrial gas boiler price list in 2023

Introduction

In the world of Industrial boilers, there are a number of different types of boilers. You can choose to buy an industrial gas-fired boiler, or you can opt for a steam boiler or even a hot water boiler. It really all depends on what type of industry you’re in and what your needs are. In this article, we’ll be looking at the pros and cons of industrial gas-fired boilers so that you can decide which one is right for your company.

What is industrial gas boiler?

industrial gas fired boiler for sale

An industrial gas boiler is a type of boiler used for industrial and commercial heating. It can be used for heating water for industrial processes or for space heating. Industrial steam boilers are also known as process steam generators because they can be used to generate high-pressure steam that’s used in industrial applications like chemical processing plants and power plants.

Because they’re very efficient, these boilers can be used in large facilities with a lot of demand for heat. They don’t require extensive maintenance either; once the installation is complete, you’ll need only to keep up with regular inspections by a professional HVAC technician so you know if there are any problems that need fixing before they become too big to handle on your own!

Need a new boiler?

How does an industrial gas boiler work?

Working principle of industrial gas boiler

Industrial gas boilers use a heat exchanger to transfer heat from the combustion process to water. The heated water is pumped through pipes to heat buildings or process water. The steam produced by the boiler is used to power turbines which produce electricity for distribution on-site or for sale back into the grid.

Gas fired industrial boilers are more efficient than oil fired boilers because they can be designed with higher temperatures and pressures, allowing them to achieve better fuel economies while producing fewer emissions of CO2 per kWh generated (CO2 being one of the most important greenhouse gases).

Which boiler is used in industry?

natural gas fired industrial boiler

Industrial boilers are used in a wide range of industries, including manufacturing, food processing, and chemical plants; power plants; refineries, and oil and gas drilling.

Industrial boilers produce steam that is used for many purposes in industry. For example:

- Steam is used to sterilize waste water before it’s returned to the environment. This prevents harmful microbes from contaminating natural waterways.

- Steam can be used as an energy source for industrial processes such as drying or purifying materials by boiling them under pressure within a closed system that traps contaminants inside the vessel so they don’t escape into the environment (known as “closed loop”).

How much do industrial gas boilers cost?

industrial gas fired boilers cost

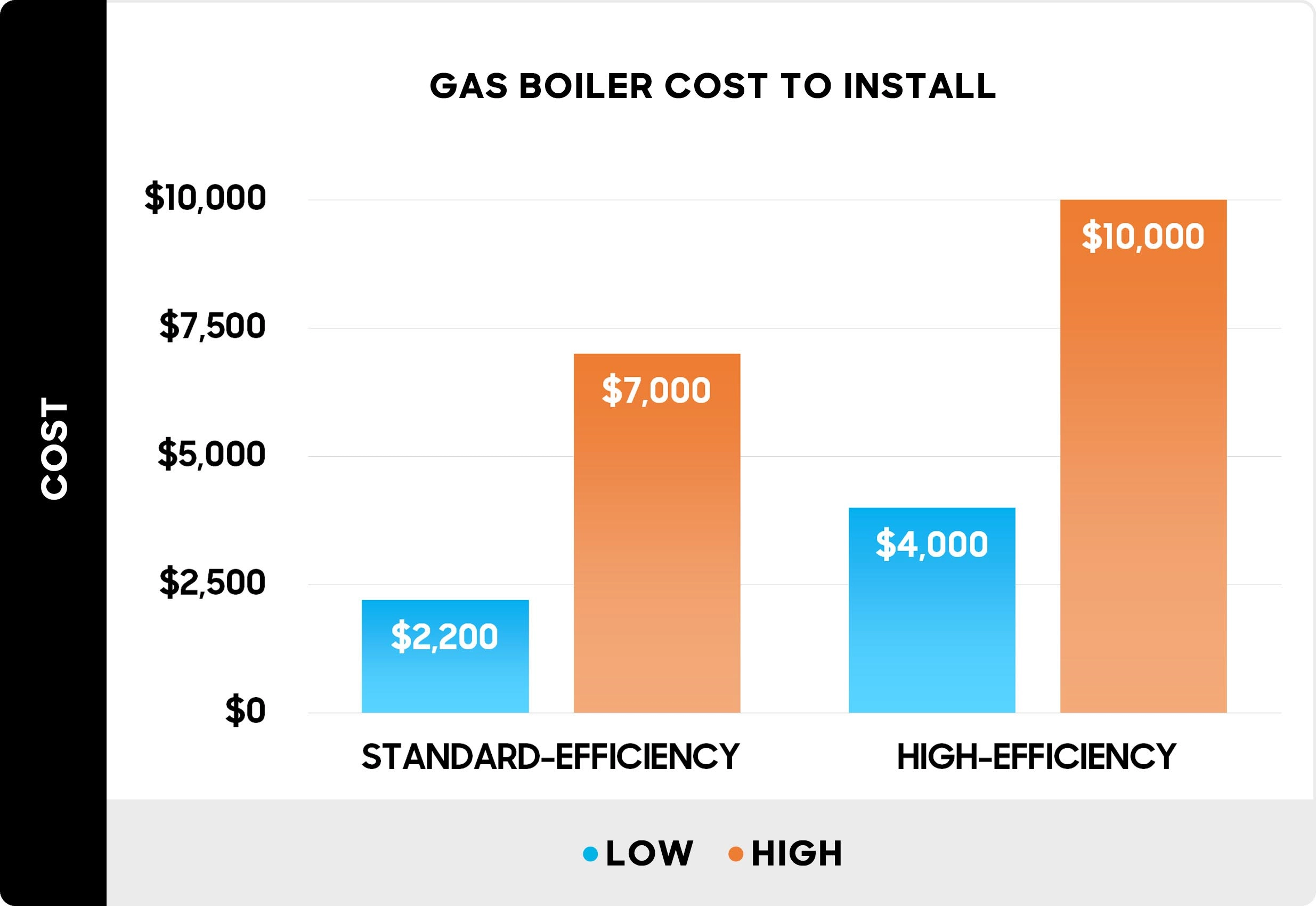

The cost of industrial gas boilers varies depending on a number of variables. For example, it depends on the size and brand of the boiler you’re purchasing; this is because larger boilers are more efficient than smaller models. Other factors that have an impact on price include whether your unit uses natural gas or propane, as well as its efficiency rating (the higher the rating, the more energy-efficient it will be).

The cost of an industrial gas boiler also depends on whether you are purchasing new or used equipment. New boilers tend to be more expensive than used models, but they also have a longer lifespan and provide better overall performance. On the other hand, used boilers may be cheaper upfront but could cost you more over time if they break down sooner than expected.

What pressure is an industrial gas boiler?

gas fired boiler vs coal fired boiler

The pressure of an industrial gas boiler is the pressure that it operates. This can be measured in pounds per square inch (psi) or kilograms per square centimeter (kPa).

The higher the pressure, the higher the temperature, and thus the more efficient a boiler becomes. The diagram below illustrates this:

As you can see from this diagram, as temperature increases so do efficiency, and vice versa.

How long do industrial gas boilers last?

How long do industrial boilers last?

Generally speaking, industrial gas boilers are built to last. We generally recommend a 20-year lifespan for all of our products. This is based on several factors, including the type of metal used in construction and the quality control procedures we implement during manufacturing. The fact that these boilers employ modern technology also contributes to their longevity; this technology allows them to run more efficiently and reduce waste heat within the system.

How efficient are industrial boilers?

Industrial Gas Boiler Efficiency

If you’re looking for a boiler that will save you money and provide excellent performance, choose an efficient industrial boiler.

Industrial boilers are more environmentally friendly and less expensive to operate than traditional boilers. They also have longer lifecycles, which means they’ll last longer without repairs or replacement.

The efficiency of your boiler can significantly impact its operating costs and overall performance, so it’s important to make sure your equipment is running efficiently before investing in new equipment or hiring professional services like ours at [Fangkuaiboiler].

Looking for boilers with sophisticated manufacturing, great quality?

Fangkuai boiler can always provide what you want.

What is the best industrial boiler?

best gas fired boiler manufacturers

The best boiler for your industrial application depends on:

- Your purpose – is it to provide hot water? Steam? How much flexibility do you need?

- Your budget – the cost of steam boilers can vary wildly, depending on what type of boiler you choose and how much power it produces.

- Your location – if there’s a lot of ambient noise around where the boiler will be located, then you may want to consider investing in a quieter model.

- The application – if it’s being used for something specific like environmental remediation or purification then check out our specialized industrial boilers section below!

How do I choose an industrial boiler?

industrial gas fired steam boiler

Choosing the right industrial boiler for your business is a complex process. Here are some questions to ask yourself before you buy:

- Safety and efficiency: You need to ensure that any new boiler you purchase is safe, efficient, and built to withstand high temperatures. Be sure to check out its ETL listing (Examination Testing & Laboratory).

- Gas or oil? This one’s pretty simple—if your business uses gas, go with a gas boiler. If not, consider an oil-fired unit instead.

- Capacity: Your building’s size will help determine how much capacity you need in terms of heating power (BTU/hr), which can be calculated by multiplying square feet times average temperature difference per degree Fahrenheit between inside air temperature and outside air temperature. For example, if it’s a 100sq ft building with an average temperature difference of 40 degrees Fahrenheit between inside air temp at 60F and outside temp at 20F then that would mean we’d need 400×40=16000 BTUs per hour from our boiler. So make sure your chosen model has enough power!

Looking for boilers with sophisticated manufacturing, great quality?

Fangkuai boiler can always provide what you want.

Conclusion

We hope that you have learned a lot about the different types of industrial gas boilers and their uses. If you need more information about choosing an industrial boiler, please contact us today! We’re always happy to help people find the right equipment for their needs.WhatsApp 0086 132 1322 2805