Руководство по ценам на промышленные электрические котлы

Введение

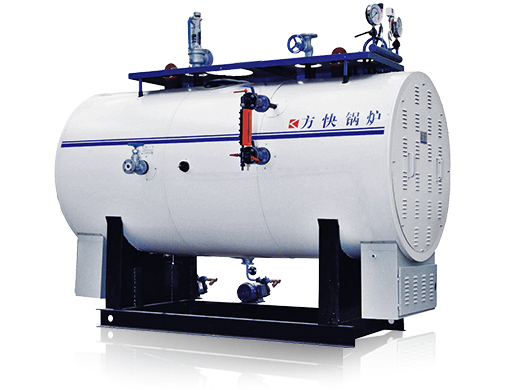

An industrial electric steam boiler is a vital boiler for business, and it can operate as the heart of your business. This machine provides you with the benefits of both efficiency and convenience, but it comes at a significant price. The high cost of an electric boiler makes it important to be well-informed about what to expect before making a purchase. In this guide, we will explore the different components that make up an electric steam boiler and how they contribute to its overall price. We’ll also take a look at common ways that these boilers are used in commercial applications so you can get an idea of how they could benefit your business if you decide to invest in one.

The industrial electric boiler price is based on the combination of its capacity, operating pressure and overall dimensions.

The industrial electric boiler price is based on the combination of its capacity, operating pressure and overall dimensions. The higher the capacity, the higher the cost, as the boiler will be able to handle more water.

The operating pressure of an industrial electric steam boiler has a direct bearing on its weight. The higher the operating pressure is set at, the heavier it becomes and vice versa. If you want to know more about this industrial product that we manufacture at our factory in India for your business or industrial use then contact us today!

The higher the capacity, the higher the cost, as the boiler will be able to handle more water.

A larger capacity boiler would be more efficient, as it can handle more water per hour. This means that you will be able to heat a greater amount of water and generate more steam. Однако, there are several other factors that play into the overall cost of the boiler:

- Higher cost for installation materials such as piping and insulation

- Greater power requirements (and thus higher energy bills) due to increased steam production and heat output

- A larger space requirement for installation

To a great extent, the operating pressure of an industrial electric steam boiler has a direct bearing on its weight.

To a great extent, the operating pressure of an industrial electric steam boiler has a direct bearing on its weight. The higher the pressure, the more energy is required to heat the water. This means that if you install a boiler with high pressure capabilities, it will be heavier than one with low pressures.

The pressure inside your boiler is determined by its steam drum size; the larger the drum size (and thus greater capacity), then you’ll need higher pressures in order to achieve high temperatures in that size of space.

How much is an industrial boiler?

The price of an industrial boiler is based on the size of the unit, operating pressure and overall dimensions. The larger the unit, the higher the price. Similarly, as operating pressures increase so do prices.

The following table outlines some typical costs associated with a variety of sizes and pressures:

How much is a commercial steam boiler?

The price of a commercial electric boiler is based on the combination of its capacity, operating pressure and overall dimensions. The higher the capacity, the higher the cost, as the boiler will be able to handle more water. Например:

- A 250-gallon hot water electric boiler costs $3,500-$4,000 (или $1.50-$1.75 per gallon), while a 500-gallon model costs around $7-$8 per gallon ($2-$2.20).

- A 4-ton steam electric pack costs around $200 per ton ($0.50/lb).

How efficient are industrial boilers?

It’s important to note that industrial boilers are more efficient than residential and commercial boilers. This is because they have larger heat exchangers, which means they can transfer heat from the water to your facility more efficiently.

The only way for a boiler system to work properly is if all of its components are working properly. If you notice something isn’t working right with your heating system, contact a licensed contractor who can diagnose and repair the problem as soon as possible.

What are the two types of electric boilers?

There are two types of electric boilers: water-tube and fire-tube.

Most industrial electric boilers utilize water-tube boilers, which have tubes through which the flue gases pass while heating up the boiler’s water. This type of boiler is more efficient than a fire-tube design because it allows the heat to be distributed evenly throughout the water tubes, leading to more consistent temperatures and increased energy efficiency.

The main difference between these two types of electric boilers is how they transfer heat from their fuel source into their water tanks. In a fire-tube system, flames travel along metal tubes inside a furnace until they reach steam generators that are submerged in cold water at the bottom of each unit; this creates steam pressure in each generator (and therefore works similarly to an oil or gas furnace).

How electric steam boilers work?

Electric steam boilers work by using electricity to heat water to create steam. The amount of energy needed to create this steam is proportional to the difference between its starting temperature and final temperature. This means that the more efficient your electric boiler, the less energy it will consume during operation.

A hot water or steam boiler works in basically the same way as an electric one, only it uses natural gas or propane instead of electricity as its fuel source. An advantage of using a hot water/steam boiler over an electric one is that there are no moving parts and therefore no mechanical wear and tear on any part of the system; this reduces maintenance costs such as oil changes or filter replacements between inspections from year-to-year because there’s nothing else besides piping itself which needs replacing so frequently!

What is the most efficient steam boiler?

The most efficient steam boilers are water boilers. The most efficient water boilers use multiple stages of heat exchange, and they have a high-quality design that reduces pressure drops through the system. Water is an excellent medium for transferring heat because it has a large specific heat capacity (the amount of energy required to raise the temperature of 1 gram by 1 degree Celsius). This means that water will absorb much more energy than other types of liquid or gas when heated or cooled over a given period of time.

A large quantity of steam can be produced by burning fuel in an industrial boiler, which then transfers its thermal energy to water via evaporation. Once boiled in this way, steam is used in many different applications at power plants and factories around the world.

The overall dimensions of a unit are critical to calculating the price of an electric steam boiler for industrial use.

The overall dimensions of a unit are critical to calculating the price of an electric steam boiler for industrial use. They include:

- The diameter and length of the boiler (or shell)

- The diameter and length of the steam tubes

- The diameter and length of the water tubes (if they are used)

- The diameter and length of flue tubes or superheater headers (if they are used). These can have a large impact on price because they take up more room.

- A draft tube is important when you calculate price as well, but not all boilers have one built into them. Some do; some don’t; it depends on whether you want one or not! Если так, just make sure that yours is big enough for what you need before ordering it.”

The amount of work required by a maintenance team to repair and/or replace parts can significantly impact its total cost.

The amount of work required by a maintenance team to repair and/or replace parts can significantly impact its total cost. Например, if an electric boiler fails due to corrosion and metal fatigue caused by regular use, the maintenance team may need to:

- Replace damaged parts

- Re-weld damaged areas

- Re-locate components that have been moved out of position during operation

Energy consumption can have a dramatic effect on the bottom line of any industrial electric boiler.

Energy consumption can have a dramatic effect on the bottom line of any industrial electric boiler. An increase of just 1% in energy efficiency will result in a reduction of up to 10% in operating costs, according to the U.S. Environmental Protection Agency (EPA). Energy consumption can significantly impact the total cost of the boiler—and that’s just one reason why you should consider replacing your current steam boiler with an electric one.

An industrial electric steam boiler is not a small investment, but with proper maintenance and careful use, it can provide significant savings over time.

A large industrial electric steam boiler can be an expensive investment, but if it is properly maintained and cared for, it can provide significant savings over time. It is important to remember that regular cleaning and testing are essential for regulation. Фактически, regular maintenance and servicing may also be required by local laws governing boilers.

The importance of proper cleaning cannot be overstated—clean systems are more efficient and less likely to break down than dirty ones. Регулярный осмотр системы поможет вам определить проблемы, прежде чем они станут серьезными проблемами, которые требуют ремонта или замены; Профилактическое обслуживание поддержат вашу систему плавно до тех пор, пока не будут необходимы эти ремонты или замены (или даже после их завершения).

Вывод

Что определяет стоимость промышленного электрического парового котла, так это его мощность и общие размеры. The higher the capacity, the higher the cost, Поскольку он способен обрабатывать больше воды и отопления. To a great extent, its operating pressure has a direct bearing on its weight and overall dimensions of a unit are critical to calculating the price of an electric steam boiler for industrial use.

Цена и стоимость электрокотла зависит от его мощности, сила, и отрасль, в которой он используется. Если вы хотите узнать больше о цене и стоимости электрокотлов, please contact us via email or whatsApp.