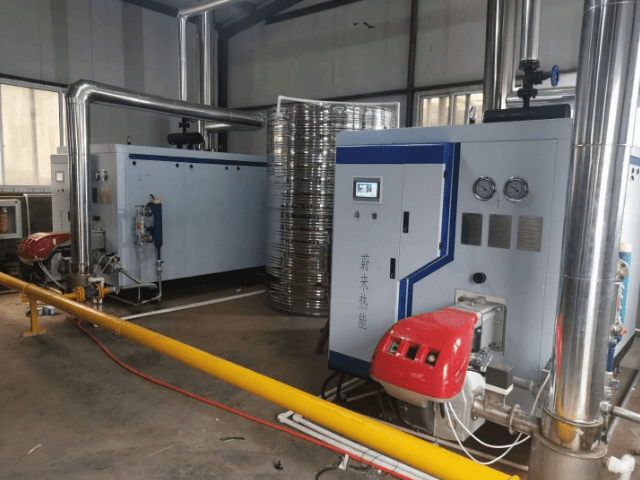

How to choose an industrial steam generator

Introduction

This article introduces the process of choosing a steam generator for industrial applications.

Calculating the total power of steam required

The first thing you should do is calculate the total power of steam required. After calculating the total power of steam required, you can then calculate the size of the industrial steam generator in order to meet this demand. The following formula can be used:

1/3 x (temperature * pressure * volume) = heat loss

The above calculation shows that if we want to get rid of all harmful gases in our system, it will be very difficult to achieve this goal because there will always be some backflow due to thermal expansion and contraction during operation. In addition, when operating at high temperatures as well as pressures, metal pipes are prone to corrosion; therefore, if not carefully controlled or checked regularly by an expert technician then they may eventually burst open resulting in heavy losses on both sides – not just financially but also environmentally!

If considering buying one then do consider its price tag first before making any final decisions since prices vary depending on different factors like type etcetera.”

How to calculate the steam generator size?

So, how do you calculate the steam generator size? There are several ways to do this.

- Use a boiler sizing calculator online. These calculators use industry standards and formulas to determine what your steam generation needs are based on your inputted data. You can find these calculators by searching “boiler sizing calculator” or “steam generator sizing calculator” in your web browser and clicking on one of the top results. Then enter some required information about your plant (location, equipment type, etc.) into their form fields and click “calculate” to get an estimate for how much steam that plant needs generated every day/month/year. The results will tell you approximately how many pounds per hour of water need converted into one pound per hour of steam – which tells us how large our generator should be!

Calculate the size of the steam distribution pipe and steam consumption?

Calculate the size of the steam distribution pipe and steam consumption?

To calculate the size of steam distribution pipe, you need to know how many m3/h and kg/h do you want to produce in order to determine whether your current manufacturing capacity is enough or not. Then according to your actual situation, choose a suitable configuration model (for example: industrial steam generator is mainly used for heating purpose). Finally select an appropriate industrial steam generator based on these two data.

industrial steam generator price

When choosing an industrial steam generator, the price can be a factor. The price of industrial steam generator is very low, and some generators are even free. If your company has no money or budget for any other equipment, we recommend that you use a generator that is not expensive and still works well.

On the other hand, if you have enough money in your budget and want to buy an industrial steam generator with more advanced features and functions than those cheaper ones, there are many different types available on the market today in terms of price range: very high-end models with high prices but excellent performance; mid-to-high end models with moderate prices but good performance; low end models which might not meet all your requirements but still work well enough given their relatively inexpensive cost

industrial steam generator for sale

Industrial steam generators are available in a variety of sizes and configurations. They can be purchased as pre-engineered packages, or they can be customized to meet specific needs.

There are four common ways to buy an industrial steam generator:

- Online

- From a local supplier

- From the manufacturer directly

- Through a distributor

Are steam generators efficient?

Steam generators are by far the most efficient way to produce steam. Boilers, boilers and steam boilers are all less than 50% efficient. This is because they require a lot of energy to heat up water and then release it as steam when needed. In contrast, a steam generator uses a process called flash evaporation which only requires around 20% of the total energy that traditional methods need to operate at peak efficiency.

What is the difference between steam generator and boiler?

The main difference between a boiler and steam generator is that the former is an enclosed system, while the latter is an open system.

A closed system has water that can’t escape, so when it heats up , it heats up. A closed system will heat its contents until they reach their boiling point or just before they hit that point. This means that there’s no way for additional heat to get into it unless you add more fuel sources or increase its temperature further.

Boiler systems are generally used in industrial settings only because they require a very large amount of energy to operate effectively and efficiently–and therefore cost a lot of money!

How long do steam generators last?

The lifespan of a steam generator is anywhere between 20-30 years. However, if you maintain your steam generators well, they can last up to 50 years or more! On the other hand, if you neglect them and use them in a harsh environment (e.g., high temperature), they may only last 5 years or so.

How big of a steam generator do I need?

The size of a steam generator is determined by the amount of steam needed to meet your needs. The size of the distribution pipe and consumption are also factors in determining how big a steam generator you need.

The first step is to calculate what percentage of your total energy needs will be met by steam generation. For example, if you operate on 80% electric power but would like to reduce that down to 50%, this means that 20% (or 1/5th) of your energy use goes through internal combustion engines that run off traditional fuels such as diesel or natural gas.

To calculate how much volume space is required for an industrial boiler:

- Find out how many kW (kilowatts) you want each boiler rated at; this number should be less than or equal to 1000 kW per boiler because larger ratings require more space for piping and valves as well as larger pumps capable enought o move huge amounts quickly without losing pressure from their own weight alone combined with centrifugal force from turning so rapidly – which can cause damage quickly if not properly managed over time.”

Which steam generator is best?

As a customer, you can choose the best steam generator in terms of your needs and budget. The most important thing is to know how to choose the right model.

To choose the correct industrial steam generator, you should consider:

- Which steam generator model is best for me?

- What are my requirements for this product?

- How much money do I want to spend on it?

What are the types of steam generators?

How to choose an industrial steam generator?

The types of steam generators include:

- Gravity steam generators. This is the most common type you’ll find on the market. It’s designed to produce a certain amount of steam at a certain pressure, whether it’s needed or not. The downside is that this kind of system wastes energy and uses more fuel than needed to generate the amount of power needed for your work environment.

- Pressure steam generators are designed specifically for high-pressure applications such as industrial processes, refineries and chemical plants (and other similar facilities). These systems use less fuel per unit time than other types because they’re built with higher efficiency in mind—meaning that they provide more power per pound of fuel consumed than other models while using less energy overall during operation itself! This makes them ideal if your business depends on heavy machinery like pumps or compressors which will require constant maintenance over time due to wear-and-tear on their parts–not only does having one installed mean less downtime during repairs but also reduces costs associated with replacement parts since there won’t be any need replacing them every year!

What fuel does a steam generator use?

- Fuel oil is a mixture of hydrocarbons that can be used as fuel. It includes kerosene and diesel, which are refined from crude oil.

- Natural gas is produced by drilling wells and extracting it from the ground (usually in liquid form). Natural gas is composed primarily of methane and other hydrocarbons, but it also contains small amounts of nitrogen, hydrogen sulfide, carbon dioxide and other gases.

- Biomass is any organic matter that can be burned to produce energy or heat (such as wood chips or corn husks). Biomass sources include woody crops such as trees or shrubs; agricultural residues like corn stalks; food processing waste such as coffee grounds; animal waste such as dung; aquatic plants such as algae; municipal solid waste including yard trimmings; paper products made from recycled paper pulp

best price steam generator

There are two types of industrial steam generators, electric and gas. Electric steam generators are the more economical choice, as they’re easier to maintain and don’t require any additional fuel source. However, their high price makes them less attractive for large facilities that consume a lot of power.

Gas-fired industrial steam generators are more expensive but have many benefits such as lower operating costs and better heat transfer efficiency than their electric counterparts. These qualities make gas-fired industrial steam generators ideal for heavy industries where large volumes of hot water or steam are required in quick succession (e.g., power stations).

Calculate the volume of steam storage.

Once you’ve determined the volume of steam that will be produced, it’s time to calculate the volume of water you’ll need to keep in storage. As stated above, one pound (0.45 kg) of water produces 0.5 pounds (0.22 kg) of steam at 212°F (100°C).

- 1 pound = 16 ounces = 4 cups = 32 tablespoons = 128 teaspoons

If your generator produces 1,000 pounds per hour and operates for eight hours per day for five days per week for 50 weeks per year then:

- 1,000 lbs/hr x 8 hrs/day x 5 days/wk x 50 wks/yr = 400 million BTU or 0.4 million British Thermal Units or 400 GJ or 400 MJ

This means that if you want to maintain a constant heat output from your generator over this time period, then you should maintain a constant reservoir size by adding water when needed so that it never drops below 80% full; otherwise it may lead to overheating issues in your system!

The choice of a suitable steam generator model.

A suitable steam generator model should be selected based on the required power of the steam generator. A large-capacity steam generator can achieve high efficiency and low operation costs in an industrial production process. The choice of a suitable steam generator model also depends on the required steam pressure, temperature, and volume. Large-capacity industrial boilers generally have a lower pressure than small-scale boilers. The higher the operating temperature is, the higher its efficiency will be; at high temperatures (above 250 degrees Celsius), chemical reactions tend to occur rapidly and efficiently in industrial processes such as cracking oils or smelting copper ore into copper sulfide powder.

The following table shows some key parameters for different types of industrial boilers:

This article helps you choose an industrial steam generator

Choosing an industrial steam generator is a complex process. You need to consider many factors.

The size of the steam generator

Power of the steam generator

Fuel used by the steam generator

Conclusion

The main function of the steam generator is to provide the heating power and process heat required by the production process. The steam generator size refers to the amount of steam generated within a certain period of time and required for steam consumption. This article helps you choose an industrial steam generator