Gas(Öl) Fired Integrated Hot Water Boiler

Gas(Öl) Fired Integrated Hot Water Boiler This series of boilers mainly use condensing technology to recover the residual heat of flue gas, making full use of the sensible heat and latent heat of flue gas. The boiler absorbs a large amount of heat again, so the exhaust gas temperature is only 50 °C, and the thermal efficiency can be increased by more than 10%, which can save at least 4% of fuel input.

Nennwärmeleistung: 0.7-14Mw

Bewerteter thermischer Wirkungsgrad: 96-98%

Druck: ≤ 1,25 mPa

Verfügbarer Kraftstoff: Erdgas, light oil, etc.

Vorteile von Erdgas(Öl) Fired Integrated Hot Water Boiler

- Low nitrogen, environmental protectionThrough the integrated solution of waste heat utilization, the exhaust gas temperature is <90 °C, reducing the emission of harmful substances.

- High efficiency and energy savingThe boiler heating surface is arranged reasonably, the heat transfer area is sufficient, and the thermal efficiency can reach 98%.

- Stable operationThe unique differential pressure detection and variable frequency continuous water supply system is more sensitive to the induction of boiler operation changes.

- Easy to operateThe boiler is equipped with a PLC intelligent operating system, which can automatically start the furnace, adjust the parameters and shut down the furnace after starting.

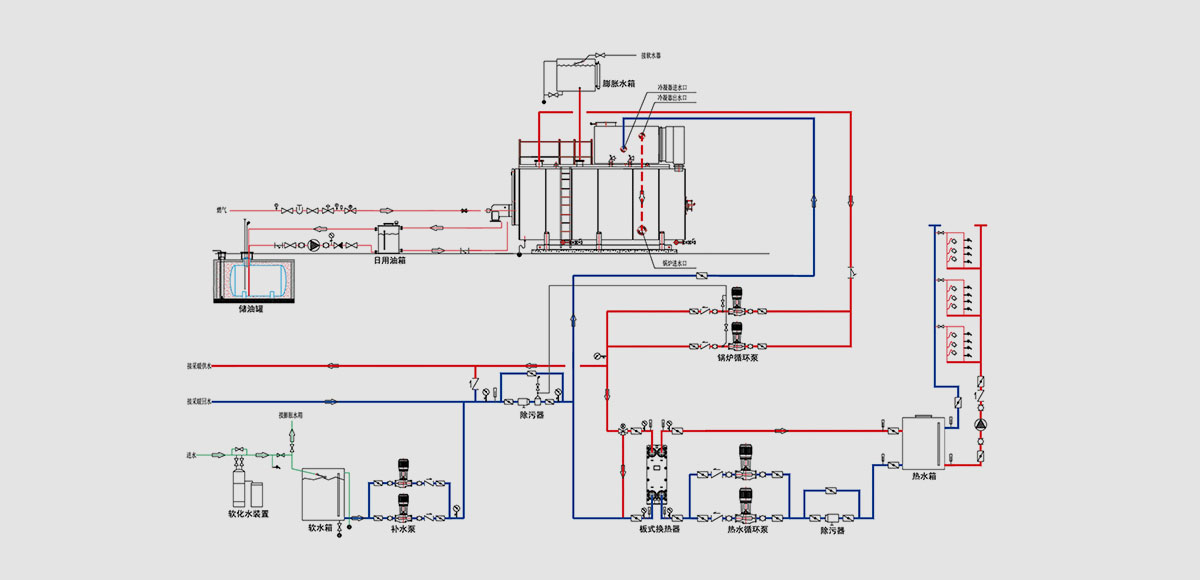

TECHNOLOGY&PROCESS

The corrugated furnace design greatly increases the heating area of the furnace and the heat is more uniform than the conventional furnace; at the same time, it prevents the furnace from breaking due to the high expansion of the high temperature combustion.

The automatic control system of PLC can realize the full automatic control of the boiler. Once the boiler is put into operation, it can automatically operate, regulate and protect the boiler. At the same time, it can switch on and off the machine regularly, which reduces the labor cost.

Gas(Öl) Fired Integrated Hot Water Boiler Anatomy

WISSENSCHAFTLICHE FORSCHUNGSSTÄRKE